Description

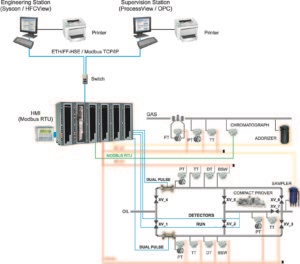

The flow computer module HFC302 in the AuditFlow is fully configurable and designed based on leading edge technology in hardware and software to measure and control corrected flow rate of liquid and gas.

- Approval for custody transfer of liquid and gas: Inmetro (Brazilian Notify Body);

- Liquid and gas measurements in the same Flow Computer Module;

- Reduced uncertainty due to digital communication with H1 FOUNDATION FieldbusTM;

- Scalable hardware: expansion of I/O modules;

- Open standards: FOUNDATION FieldbusTM, OPC, HART®, Modbus RTU, Modbus TCP/IP, Ethernet TCP/IP;

- Calculations for temperature and pressure compensation with ISO, AGA, API, GPA and ABNT standards;

- Well test: comprehensive report of test including measurement of crude oil, produced natural gas (discounted of gas lift) and water;

- HFCView – Report and Management Tool: automatic generation of XML report meeting ANP requirements, reports stored in database (SQL or Access);

- Supported flowmeters for liquid: turbine, ultrasonic, coriolis, positive displacement;

- Liquid products supported: crude oil, refined products, lubricating oil, emulsion of crude oil and water, ethanol;

- Allocation Measurement: correction factors and proving to measure emulsion of crude oil and water;

- Linearization curve of KF/NKF/MF factors by frequence /flow rate for liquid measurement;

- Level A in fidelity and security pulse transmission: continuous verification and correction by comparison of pulses A and B;

- Prover types supported: Piston, ball, tank and master meter;

- Supported flowmeters for gas: differential pressure, turbine, ultrasonic, Coriolis, VCone, Wafer Cone;

- Gas products supported: natural gas, steam, argon, oxygen, nitrogen, carbon dioxide, ammonia;

- Communication with gas analyzers through Modbus and FOUNDATION FieldbusTM;

- Batch types : quantity, time and interface;

- Configuration language: function block diagram for flow calculation, logic ladder for interlocking and sequencing, PID control, sampler/odorizer control.